Shopfloor Integration

Success factor for Industry 4.0 : The PAC platform combines integration and automation of the shopfloor

- Home

- Smart Factory

- Shopfloor Integration

Shopfloor Integration is critical to the success of Smart Manufacturing

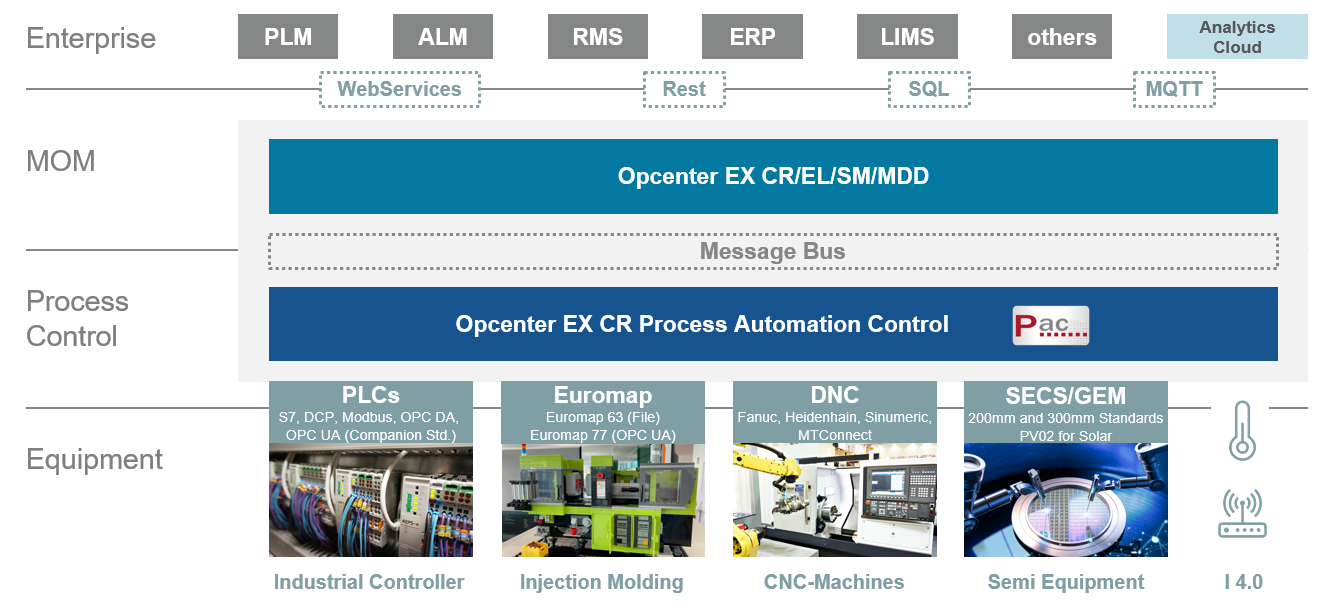

Seamless Shopfloor Integration is the key precondition for the implementation of Industry 4.0, Smart Manufacturing and Smart Factory concepts. Two aspects are most essential in this context:

-

Integration of all machines, systems, sensors and user interfaces of the shopfloor into the central IT systems of the MOM level

-

Communication of the shopfloor systems among each other

The first aspect assigns the MES the task to ensure correct manufacturing: product, specification, quantity, time, manufacturing specifications (machine recipe), etc. The actual execution should take place on one of the lower levels. A corresponding shopfloor integration layer unburdens the MES of all details of shopfloor control and communication. The second aspect considers the direct communication within the shopfloor level to independently solve subtasks in the manufacturing process.

Through a specific integration logic, our integration platform PAC achieves a standardization of the information from the equipment level for a transfer to higher-level systems of the MOM level. PAC enables control of the entire integration level and can optionally take over cross-machine manufacturing control.

Success factors for shopfloor integration

Shopfloor Integration is a central component of Industry 4.0 concepts. Integration platforms acting as a separate equipment integration layer, which aggregate and contextualize Shopfloor data, create the best possible prerequisites:

Connection of all machines to all relevant systems at equipment, MOM and enterprise level, under consideration of the different target system data requirements.

Simple connection of additional machine types as well as further machine instances without limiting performance.

Automation in the form of a Data Collection, Basic Automation, Advanced Automation, Full Automation and realization of various automation scenarios.

Direct communication within the shopfloor level to independently solve subtasks in the production process.

Guidelines for the product, specification, quantity, timing, machine recipes, etc. are provided centrally from the MES for implementation at the shopfloor level.

Decoupling the complexity of shopfloor control and communication through a separate equipment integration layer that aggregates and contextualizes shopfloor data.

One solution for shopfloor integration and automation

Market-leading equipment integration platform PAC

Our PAC (Process Automation Controller) is a powerful, open platform that enables equipment integration and automation